[ad_1]

Choosing the right material is essential for any application, especially those designed for washout, corrosion resistance, heat resistance, or strength. There are a variety of materials to choose from with many different specifications attached to them. Stainless steel is a popular and affordable choice in the packaging industry, especially for food grade applications. In this article, we dissect stainless steel and the different shades of each.

Types of stainless steel alloys

The main types of stainless steel alloys are austenitic, ferritic, martensitic, duplex and precipitation hardening stainless steels. The most used and popular is austenitic. Austenitic stainless steel is non-magnetic and its structure allows the material to harden. The austenitic stainless steel subgroups are 300 and 200. We will review the main grades of stainless steel in the 300 subgroups as these are the most used grades.

Stainless steel 303 vs. 304 vs. 316

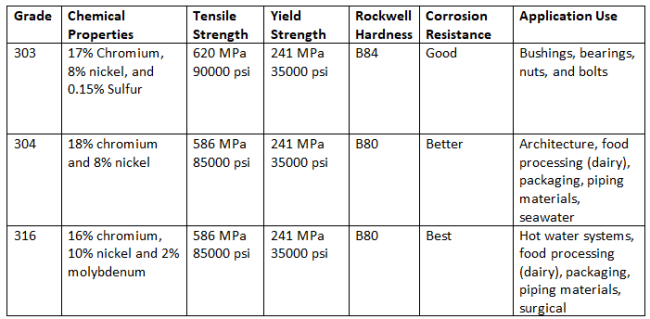

Stainless steel 304 is a low carbon steel that contains a minimum of 18% chromium and 8% nickel, which gives the metal its other name: 18/8 stainless steel. This type of stainless steel is resistant to oxidation and corrosion. This durability facilitates manufacture and the prevention of product contamination. 304 stainless steel is considered the most versatile and common austenitic stainless steel and is more cost effective than 316 stainless steel.

303 is a free-cutting grade of 304 stainless steel that contains a minimum of 17% chromium, 8% nickel and 0.15% sulfur / selenium. The small addition of sulfur slightly reduces corrosion resistance but increases machinability, which is why you will find its use in fasteners, bushings, bearings and other smaller components. These components require more precise machining specifications due to the tolerances required. While 303 stainless steel still has strong corrosion resistance, for an added boost, 304 stainless steel is recommended.

316 stainless steel contains a minimum of 16% chromium, 10% nickel and 2% molybdenum. The main difference between 304 and 316 stainless steel is that 316 stainless steel contains a significantly increased amount of molybdenum. The addition of this transition metal increases the corrosion resistance of 316 and also provides high heat resistance up to 1600 ° F. Similar to 304 stainless steel, 316 stainless steel is a chrome-nickel stainless steel. If the environment contains large amounts of corrosive elements and / or materials that would be placed under water, 316 stainless steel is a preferred choice.

300 Series Stainless Steel Mechanical Components

Whether your application requires 316 or 304 stainless steel, MISUMI offers a variety of configurable 300 grade stainless steel components including plates, tubing, fittings, tubing, fasteners, and rods / bars to meet your requirements. your needs. Visit our product highlight page for MISUMI’s offerings.

https://www.misumiusa.com

[ad_2]