Stainless steel has many material advantages for a range of industrial applications, but the processing technology chosen can affect the quality and integrity of parts and components made from this versatile metal.

This article assesses the rationale for using stainless steel for a range of parts and components, and examines the role of photochemical etching as a processing technology to produce innovative and highly accurate end-use products. .

Why stainless steel?

Stainless steel is basically low carbon steel that contains 10% or more chromium by weight. The addition of chromium gives the steel its unique properties of stainless steel and resistance to corrosion. The chromium content of steel allows the formation of a hard, adherent, invisible and corrosion resistant chromium oxide film on the steel surface. If damaged mechanically or chemically, this film is self-healing, provided oxygen – even in very small quantities – is present.

The corrosion resistance and other useful properties of steel are improved by increased chromium content and the addition of other elements such as molybdenum, nickel and nitrogen.

Stainless steel has many advantages. First of all, the material is resistant to corrosion, chromium being the alloying element which gives this quality to stainless steel. Low alloy grades resist corrosion in atmospheric and pure water environments; high-alloy grades can resist corrosion in most acids, alkaline solutions, and chlorine-containing environments, making their properties useful in process plants.

Special high chromium and nickel alloy grades resist scaling and retain high strength at elevated temperatures. Stainless steel is widely used in heat exchangers, superheaters, boilers, feedwater heaters, valves and mainlines as well as aircraft and aerospace applications.

Cleanliness is also a matter of great importance. The ease of cleaning of stainless steel makes it the first choice for strict hygienic conditions, such as hospitals, kitchens and food processing plants, and the shiny and easy-to-maintain surface of stainless steel offers a modern and attractive appearance.

Finally, on the cost side, and considering material and production cost and life cycle cost, stainless steel is often the cheapest material option and is also 100% recyclable, thus complementing the complete life cycle.

Photochemical etching

The Micrometal Etching Group (comprising HP Etch and Etchform) etches a variety of metals with precision unmatched anywhere in the world. The thickness of sheets and processed sheets ranges from 0.003 to 2000 µm. Stainless steel, however, remains the number one choice for many of the company’s customers due to its versatility, numerous grades available, large number of related alloys, favorable material properties (as mentioned above above) and the wide range of finishes. It is the metal of choice for many applications in a wide range of industries, micrometal specializing in the processing of 1.4310: (AISI 301), 1.4404: (AISI 316L), 1.4301: (AISI 304), and austenitic metals well-known, a variety of ferritic, martensitic (1.4028 Mo/7C27Mo2) or duplex, Invar and alloy 42 steels.

Compared to traditional sheet metal working technologies, photochemical etching (which produces precision components by selectively removing metal through a photoresist mask) has several inherent advantages. Most importantly, photochemical etching produces parts while eliminating material degradation because no heat or force is used during processing. Additionally, the process can produce parts of almost unlimited complexity as component features are simultaneously removed using etching chemicals.

Tooling for engraving is either digital or glass, so there’s no need to start cutting out expensive, hard-to-fit steel molds. This means that large quantities of product can be reproduced with absolutely zero tool wear, ensuring that the first and the millionth part produced are the same.

Digital and glass tooling can also be adapted and changed extremely quickly and economically (often in less than an hour), making them ideal for prototypes and high-volume production runs. This allows for “risk-free” design optimization without financial penalty. Turnaround time is estimated to be 90% faster than for stamped parts, stamping also requires a substantial initial investment in mold making.

Meshes, filters, sieves & flexures

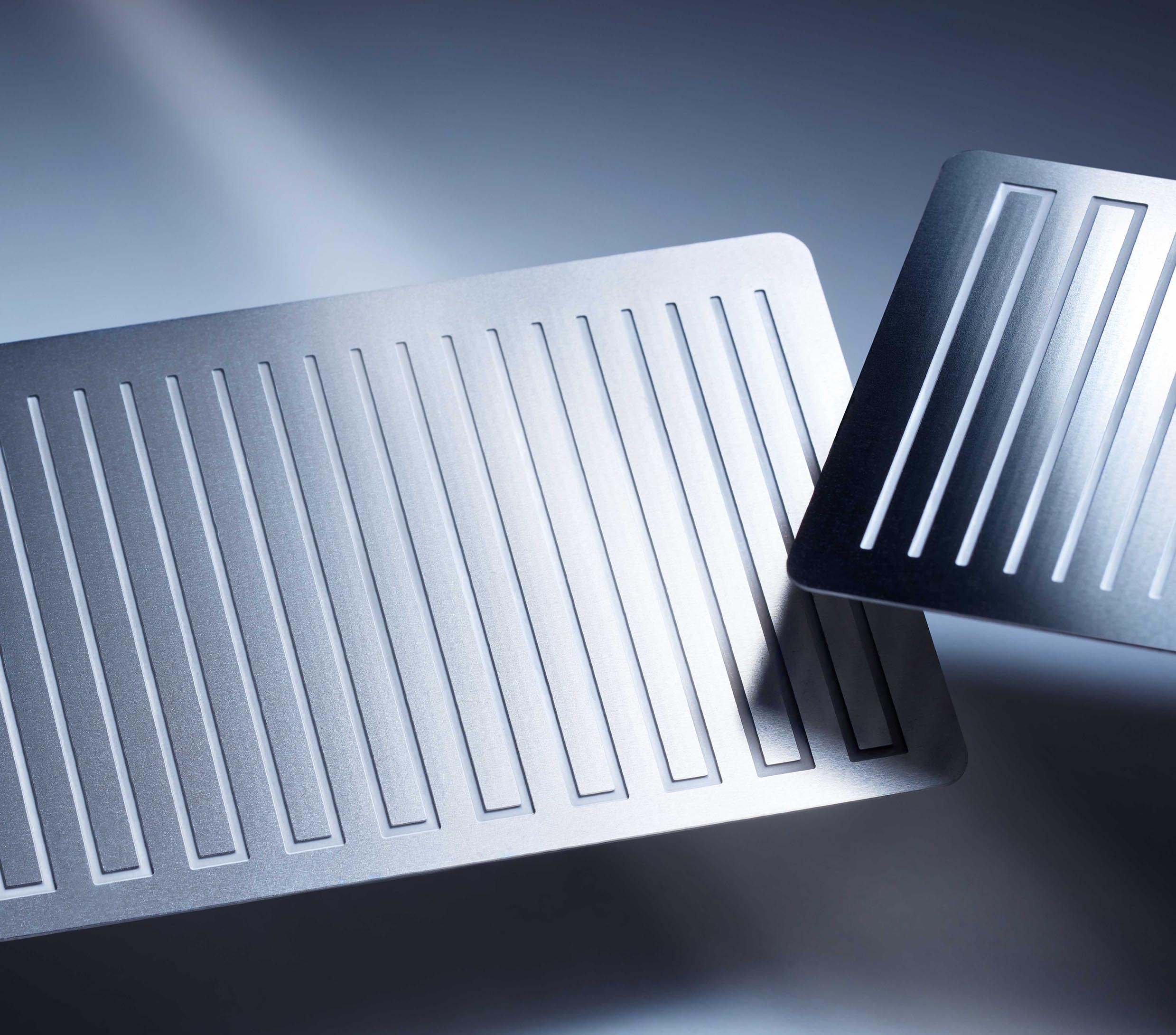

The company can engrave a range of stainless steel components including mesh, filters, screens, flat and flexible springs.

Filters and sieves are required by many industrial sectors, and customers often require complexity and the achievement of very high precision parameters. The micrometal photochemical etching process is used to manufacture a range of filters and screens for applications in the petrochemical industry, food industry, medical sector and the automotive industry (which uses photoetched filters due to their high tensile strength in fuel injection systems and hydraulic devices). micrometal has developed its photochemical etching technology to allow exact control of the etching process in 3 dimensions. This facilitates the creation of complex geometries and, when applied to the manufacture of meshes and sieves, significantly reduces lead times. Additionally, special features and various opening shapes can be included in a single mesh without increasing cost.

Unlike conventional machining technologies, photochemical etching offers higher levels of complexity when producing thin, precision steel meshes, filters and screens.

Since metal is removed simultaneously during etching, multiple aperture geometries can be incorporated without incurring high tooling or processing costs, and where perforated sheets are prone to distortion, the photo-etched mesh is burr-free and stress-free with zero material degradation.

Photochemical etching does not alter the surface finish of the material being processed, as no metal-to-metal contact or heat source can alter surface properties. As such, the process can provide a unique highly aesthetic finish on stainless steel that makes it suitable for decorative applications.

Photochemically etched stainless steel components are also often used in safety critical applications or in extreme environments, such as ABS braking systems and fuel injection systems. steel. Alternative processing technologies such as machining and wiring often leave small burrs and recast layers that can compromise spring performance.

Photochemical etching eliminates potential fracture sites in the grain of the material, producing flexes free of burrs and remelted layers, ensuring long product life and greater reliability.

Summary

Steel and stainless steels have an array of characteristics that make them ideal for many pan-industrial applications. Although considered a relatively simple material to process using traditional sheet metal working technologies, photochemical etching offers manufacturers significant advantages when producing complex and safety-critical components.

Engraving requires no hard tooling, allows rapid scale-up from prototype volumes to high-volume manufacturing, offers nearly unlimited part complexity, produces burr-free and stress-free components, does not affect condition and metal properties, suitable for all grades of steel, and achieving an accuracy of ±0.025mm, all in times measured in days, not months.

The versatility of the photochemical etching process makes it a compelling option for fabricating stainless steel parts in many demanding applications, and drives innovation by removing barriers for design engineers inherent in traditional sheet metal working technologies.