[ad_1]

Driven by the exponentially increasing demand for cutting instruments from a plethora of manufacturing industries, the global market tool steel market, is emerging as one of the most lucrative verticals in the steel industry. Tool steel – a category of carbon and alloy steels which are well suited and widely used for making tools which are primarily used in fabrication and perforation, is significantly different from the steel generally used in consumer goods because it is produced on a smaller scale with very strict quality requirements.

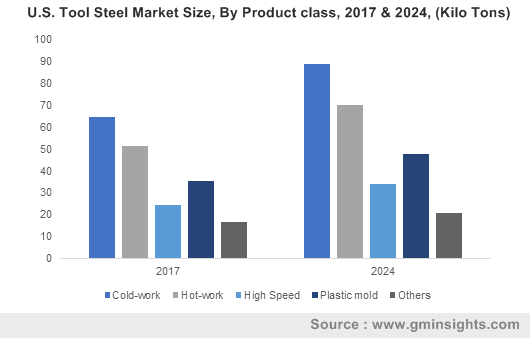

United States Tool Steel Market Size, by Product Class, 2017 and 2024, (Kilo Tons)

Steel finds extensive use in the manufacture of tool bits, gear cutters, planers, router bits, punches, taps and drills. Tool steel also offers a plethora of advantages for cutting tool manufacturers, ranging from high level thermal conductivity to cheaper machinability and wear resistance while allowing for better polishing quality. Ideal for deployment in a multitude of industrial fields, the product is attracting considerable attention, thus propelling the commercialization scale of the tool steel market. In this regard, it is safe to mention that one of the most profitable verticals that deploy tool steel is the automotive sector.

Around the world, the automotive industry has undergone some kind of revolutionary expansion, possibly driven by the increased demand for automobiles that has resulted from the increase in globally disposable incomes and standards that come into play regarding the quality and safety of vehicles. Speaking of the latter, it is safe to mention that in the production of vehicles, elements such as molybdenum, a highly ductile corrosion resistant metal with one of the highest melting points of all pure elements, and chromium, a malleable metal that is highly resistant to corrosion, are usually combined. with steel to create alloys. These alloys are significantly stronger than their pure counterparts in terms of tensile strength and corrosion and heat resistance to produce flywheels and vehicle clutches, among other components.

Chromium Molybdenum Tool Steel, commonly referred to as a Chromium Molybdenum Steel Alloy, is ideal for critical automotive applications due to its excellent strength-to-weight ratio and ability to perform in demanding environments while allowing better energy efficiency due to its low weight. These properties have made the alloy a critical part of an automobile’s internal manufacturing profile, creating a positive growth chart for the tool steel market by 2024.

While the alloy is undoubtedly beneficial, it is essential to state that molybdenum, on its own, is also a very reliable tool steel, as it helps improve hardening ability, wear resistance and durability. toughness of the final product. Steel is also deployed in cold work projects such as cutting tools – automotive end mills, end mills and cam rings as well as punching and cutting dies, causing the size of the steel market to molybdenum-based tools, which is expected to register a CAGR of 4% over 2018-2024.

Unveiling US Tool Steel Market Trends

The United States has become one of the most proliferating regions in the global tool steel market, given the importance of the aviation industry to the country. Aerospace manufacturing is considerably unique among other manufacturing sectors. There is also a high process risk in terms of machining aerospace parts as the margin for error is almost non-existent when cruising 35,000 feet above the ground.

Tool steels generally find applications in a number of different regions of an aircraft which are subjected to significantly higher stresses throughout the life of the aircraft. According to a report from Aerospace Manufacturing, chrome tool steel is ideal for use as anti-friction bearing rollers and balls because of its high strength and hardness. In addition, the metal is also used in H11 tool steel bolts because they have immense resistance to stress, thermal fatigue, impact and coarse cracking. These bolts are ideal for use in landing gear.

Very openly, driven by the regional aerospace industry, the US tool steel market is expected to generate considerable profits by the end of 2024. In fact, the size of the US hot work tool steel market is expected to register a CAGR of 4.5% from 2018. -2024, fueled by product usage in the rapidly expanding regional oil and gas industry.

China Tool Steel Market Trends Unveiled

China is another region that is expected to accumulate substantial returns for the global tool steel market in the coming years. As the country experiences an escalation in demand for air travel due to increased disposable income, the need for tool steel in aerospace manufacturing is set to increase. In addition, the region is aware of government initiatives put in place to attract more investment in the aviation sector of the country. China’s tool steel market share is estimated to exceed $ 70 million by 2024.

Attributed to commendable growth in both developed and developing economies, the global tool steel market is poised to remain one of the most profitable investment grounds for stakeholders. According to a report by Global Market Insights, Inc., the market size for tool steel is expected to exceed $ 6.5 billion by 2024.

[ad_2]