Uniformity Laboratories announced the availability of its ultra-low porosity 17-4PH stainless steel powder for the Metal desk Buy the Pro Binder Jetting platform. 17-4PH is an advanced metal powder that the company claims provides superior material properties, geometric accuracy of sintered parts, processing yield and print uniformity at the highest throughput.

Some of the characteristics of the powder:

- Tapping density of 5.33 ± 0.05 g/cm3

- Sintered density of 7.68 ± 0.03 g/cm3

- Deviation in brown density when printed +/- 0.024 g/cm3

- Parameters on average 4.49 +/- 0.05g/cm3

- Sinter shrinkage of 15.17% ± 0.65% in X direction, 15.66% ± 0.65% in Y direction and 18.18% ± 0.63% in Z direction

The reported process stability is made possible by the low cohesive, low porosity powder that spreads evenly across the build bed. Uniformity claims that the high brown densities result in up to 50% reduction in linear shrinkage over competing materials and deliver 99-100% final part density for best-in-class material properties.

The free-flowing nature of the powder improves flow by allowing rapid layering. The company states that this provides a net throughput advantage of approximately 50% over non-uniform powders on comparable platforms. The uniformity indicates that this enables part manufacturers to take advantage of a substantial reduction in costs who plan to adopt metal AM on a large scale.

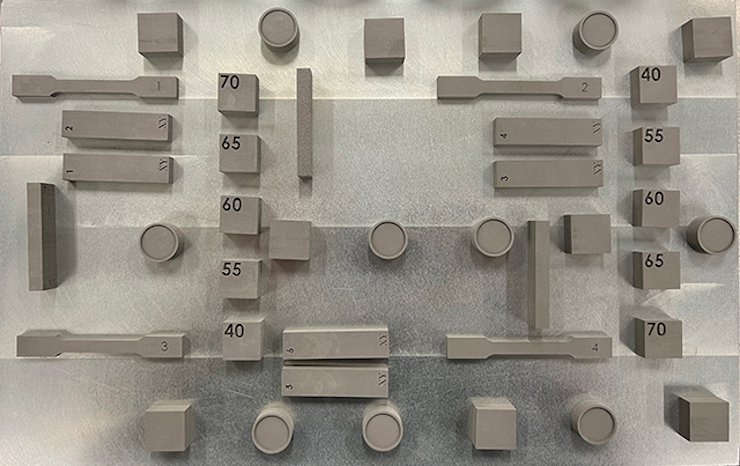

The fluidity of Uniformity’s low cohesive powders makes it much easier to depowder high aspect ratios and geometrically complex parts with fine features and channels. This prevents breakage during the depowdering stage of the process and allows for the binder jetting of more complex, high aspect ratio parts.

17-4PH is a martensitic precipitation hardened stainless steel known for its corrosion resistance, high strength and hardness, especially when heat treated. The powder can be heat treated to varying levels of hardness and toughness, allowing users to customize the post-sintering properties of the alloy to suit a variety of applications, such as chemical processing, machinery manufacturing and food processing.

“Uniformity’s use of 17-4PH stainless steel for BJT provides mechanical and process excellence to our customers who require materials that meet the highest standards at every stage of the production process,” said the Uniformity founder and CEO, Adam Hopkins. “Our powders offer superior mechanical properties, surface finish, print yield and process stability, allowing one machine to do the job of many.”

Want to discuss ? Join the conversation on the Discord of the global additive manufacturing community.

Get your FREE print subscription to TCT Magazine.