Updated by Ibtisam Abbasi on 05/03/2022

Topics Covered

Introduction

Chemical composition

Mechanical properties

Other designations

Manufacturing and heat treatment

Hardening

Annealed

Cold operation

Welding

To forge

Forming

Machinability

Thermal treatment

Hardening

Introduction

Alloy steels include a wide range of steels whose compositions exceed the Si, Va, Cr, Ni, Mo, Mn, B and C limits assigned to carbon steels. These steels contain elements such as chromium, cobalt, nickel, etc.

Compared to carbon steels, alloy steels are much more reactive to mechanical and thermal treatments. Alloy steels can be subjected to unique smelting and deoxidation processes for specific types of applications.

AISI 9310 alloy steel is a low alloy steel containing molybdenum, nickel and chromium. The following data sheet provides an overview of AISI 9310 alloy steel.

Comparison Between Alloy Steel and Carbon Steel

Besides iron and carbon, alloy steel contains a significant amount of alloying materials. Carbon alloy, on the other hand, has a high concentration of carbon and a low fraction of other elements. There is up to 2.1% carbon by weight in carbon alloys; other elements have no minimum level and are generally classified as contaminants. The strength of carbon steel is higher than that of alloy steel.

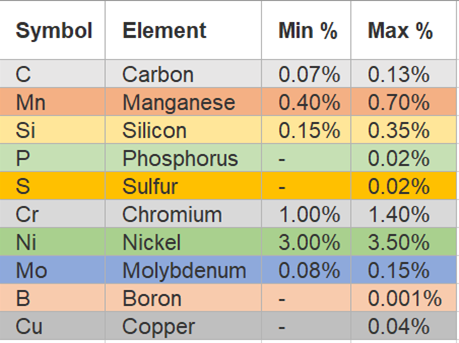

Chemical composition

The chemical composition of AISI 9310 alloy steel is described in the following table.

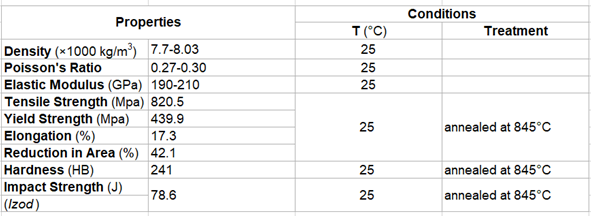

Mechanical properties

The mechanical properties of AISI 9310 alloy steel are shown in the following table.

Other designations

Materials equivalent to AISI 9310 alloy steel are:

- AMS 6260G

- AMS 6265C

- AMS 6267A

Hardening

AISI 9310 alloy steel is typically hardened to 149°C (300°F).

Annealed

AISI 9310 alloy steel is annealed at 857°C (1575°F) and then slowly cooled in the furnace.

Cold operation

Conventional methods are used to cold work AISI 9310 alloy steel which has good ductility in quenched and tempered conditions.

Welding

AISI 9310 alloy steel has good weldability characteristics because it can be welded by a standard process with the use of established welding methods.

To forge

AISI 9310 alloy steel is forged at 1191°C (2175°F) up to 927°C (1700°F).

Forming

AISI 9310 alloy steel can be easily formed by conventional procedures as this steel has good ductility even in the tempered and quenched condition.

Machinability

AISI 9310 alloy steel can be machined by conventional methods and good results are obtained when this alloy steel is machined in the hardened or annealed condition.

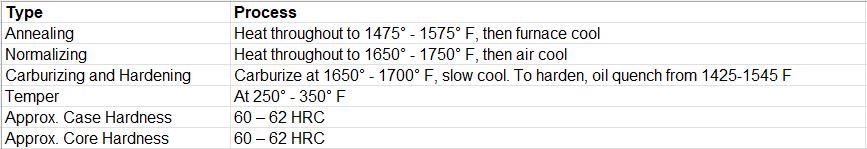

Thermal treatment

General heat treatment methods are summarized below in the table.

Hardening

AISI 9310 alloy steel can be hardened by cold working or by heat treatment and oil quenching.

AISI 9310 alloy steel after pseudo-carburizing

Pseudo-carburizing, also known as isothermal holding without a carburizing environment, is commonly used to model the progression of the morphological microstructure of gears during carburizing. The properties of AISI 9310 alloy steel after pseudo-carburizing are as follows: