Corrosion of steel structures is a significant global problem that leads to substantial economic and environmental consequences. The degradation of steel due to corrosion not only compromises the structural integrity but also increases maintenance costs and reduces the lifespan of infrastructure. To combat this issue, various methods have been developed to enhance the corrosion resistance of steel. One such method is electrochemical techniques, which involve applying an electric current or potential to modify the surface properties of steel and create a protective barrier against corrosive agents.

For instance, consider a hypothetical case study where a bridge located in a coastal region experiences severe corrosion due to exposure to saltwater. Traditional approaches such as coating with paints or inhibitors may be insufficient for long-term protection. In contrast, electrochemical methods offer promising solutions by utilizing principles like cathodic protection (CP) and electroplating. By applying CP on vulnerable areas of the bridge structure, sacrificial anodes can be employed to provide electrons that reduce corrosive reactions at those sites. Similarly, through electroplating, a thin layer of another metal with high corrosion resistance can be deposited onto the surface of the steel, forming a protective coating that inhibits further deterioration.

In recent years, research efforts have focused on advancing these electrochemical techniques to improve their efficiency and effectiveness in providing long-term corrosion protection. For example, researchers are exploring the use of nanomaterials and coatings with enhanced properties to increase the durability and adhesion of protective layers. Additionally, advancements in monitoring and control systems have allowed for real-time monitoring of corrosion rates and adjustment of electrochemical parameters for optimal protection.

Furthermore, studies are being conducted to better understand the mechanisms behind corrosion initiation and propagation at a molecular level. This knowledge can help in designing more targeted and efficient electrochemical methods for corrosion prevention. Additionally, efforts are underway to integrate these techniques into sustainable infrastructure design practices by considering factors such as energy consumption, material selection, and life cycle analysis.

Overall, electrochemical techniques offer great potential in mitigating steel corrosion and extending the lifespan of structures. Continued research and development in this field will contribute to the advancement of corrosion protection strategies and ultimately lead to safer, more durable infrastructure worldwide.

Importance of Electrochemical Methods in Corrosion Prevention

Importance of Electrochemical Methods in Corrosion Prevention

The detrimental effects of corrosion on steel structures are well-known and widely documented. From bridges to pipelines, the integrity and longevity of these vital infrastructures can be compromised by rust and degradation over time. This not only poses significant safety risks but also leads to substantial economic losses for industries worldwide. Therefore, finding effective methods to prevent or mitigate corrosion has become a critical area of research.

To illustrate the importance of electrochemical methods in corrosion prevention, let us consider a hypothetical scenario involving an offshore oil rig subjected to harsh marine conditions. Without proper protection, the constant exposure to saltwater would gradually corrode the steel structure, jeopardizing its stability and functionality. However, by employing advanced electrochemical techniques such as cathodic protection or impressed current systems, it becomes possible to significantly reduce the corrosive damage caused by electrolytic processes.

By utilizing electrochemical approaches, several key benefits can be achieved in corrosion prevention:

- Enhanced durability: Electrochemical methods provide an active defense against corrosion, offering long-lasting protection that conventional coatings alone cannot guarantee.

- Localized effectiveness: These techniques target specific areas prone to corrosion rather than applying uniform protective measures across an entire structure.

- Reduced maintenance costs: By implementing efficient corrosion prevention strategies upfront, costly repairs and downtime due to structural failures can be minimized.

- Environmental sustainability: Electrochemical methods often produce less waste compared to traditional anti-corrosion practices like coating removal and replacement.

To further emphasize the significance of electrochemical techniques in combating corrosion, we present a table highlighting their advantages over other commonly employed preventive measures:

| Traditional Methods | Electrochemical Methods |

|---|---|

| Passive barrier (coatings) | Active protection |

| Vulnerable to physical damage | Self-healing capabilities |

| Limited service life | Long-term effectiveness |

| High maintenance requirements | Reduced need for upkeep |

In summary, electrochemical methods play a crucial role in corrosion prevention by offering enhanced durability, targeted protection, reduced maintenance costs, and environmental sustainability. Understanding the mechanisms behind steel corrosion will enable us to develop more effective strategies, which we will delve into in the subsequent section.

(Transition) By comprehending the intricacies of steel corrosion mechanisms, we can further refine our approaches and optimize electrochemical methods to combat this pervasive issue effectively.

Understanding the Mechanisms of Steel Corrosion

Having established the importance of electrochemical methods in corrosion prevention, we now turn our attention to understanding the mechanisms behind steel corrosion. To illustrate these mechanisms and their implications, let us consider a hypothetical scenario where a coastal bridge is constantly exposed to saltwater spray.

In this scenario, when saltwater comes into contact with the steel surface of the bridge, an electrochemical reaction occurs that leads to corrosion. The three main stages involved in this process are initiation, propagation, and termination.

The initiation stage begins with the absorption of chloride ions onto the steel surface due to exposure to saltwater spray. These chloride ions create local areas of high acidity and disrupt the passive film that normally protects the steel from corrosion. As a result, iron atoms on the surface start dissolving into solution as ferrous ions (Fe²⁺), leading to localized pitting corrosion.

During the propagation stage, once pits have formed on the steel surface, oxygen diffuses towards these sites and reacts with Fe²⁺ ions. This reaction produces hydroxide ions (OH⁻) which combine with more Fe²⁺ ions to form insoluble rust deposits. Over time, these rust deposits further accelerate both pit growth and general metal loss across larger areas of the steel surface.

- Chloride ion absorption leads to local areas of high acidity.

- Disruption of passive film allows for iron dissolution.

- Pits form on steel surfaces due to localized corrosion.

- Oxygen diffusion accelerates pit growth and metal loss.

Now let’s delve deeper into how each stage contributes to overall corrosion by presenting a table highlighting key characteristics:

| Stage | Description | Implications |

|---|---|---|

| Initiation | Absorption of chloride ions creates acidic conditions; passive film disruption | Localized pitting corrosion occurs |

| Propagation | Oxygen diffuses towards pits; rust deposits form | Accelerated pit growth and metal loss |

| Termination | Corrosion reactions cease due to depletion of reactants | Metal degradation stabilizes or slows down |

By understanding these mechanisms, we can now explore electrochemical techniques for surface modification in the subsequent section. Through targeted modifications, we aim to mitigate the effects of steel corrosion and enhance its resistance against environmental factors such as saltwater spray.

Transition into the subsequent section:

Building upon this knowledge, let us now delve into Electrochemical Techniques for Surface Modification that offer promising solutions in preventing steel corrosion.

Electrochemical Techniques for Surface Modification

Steel corrosion is a complex electrochemical process that involves multiple stages and mechanisms. In the previous section, we discussed how steel corrodes and the factors that influence its corrosion rate. Now, we will delve into the realm of electrochemical techniques for surface modification to enhance steel’s resistance to corrosion.

To better comprehend the significance of these techniques, let us consider an example. Imagine a coastal bridge made from structural steel exposed to harsh marine environments. Over time, this bridge begins to show signs of corrosion due to exposure to saltwater and atmospheric pollutants. To protect against further deterioration, researchers have explored various electrochemical methods as potential solutions.

Electrochemical techniques offer several advantages in enhancing steel’s corrosion resistance. Here are some key points worth noting:

- Surface passivation: By using electrochemical processes such as anodization or conversion coatings, a protective barrier layer can be formed on the steel surface. This passivation layer acts as a shield against corrosive agents.

- Electroplating: Through electrodeposition, a thin layer of metal with superior corrosion resistance (e.g., chromium) can be plated onto the steel substrate. This provides an additional protective coating that inhibits corrosion.

- Cathodic protection: Employing sacrificial anodes or impressed current systems helps direct cathodic currents onto the steel surface, effectively reducing its susceptibility to oxidation reactions.

- Smart coatings: The development of self-healing coatings has gained significant attention in recent years. These smart coatings possess intrinsic healing properties that repair any damage caused by mechanical wear or localized corrosion.

Table 1 below summarizes some commonly used electrochemical techniques along with their advantages and limitations:

| Technique | Advantages | Limitations |

|---|---|---|

| Anodization | Enhanced passive film formation | Limited control over coating thickness |

| Electroplating | Uniform deposition | High cost and potential environmental impact |

| Cathodic protection | Effective for large structures | Requires regular maintenance |

| Self-healing coatings | Autonomous repair of damaged areas | Limited availability and high complexity |

Moving forward, we will explore the role of electrochemical coatings in corrosion protection. By understanding how these coatings function at a molecular level, we can gain insights into their effectiveness in preventing steel corrosion.

Role of Electrochemical Coatings in Corrosion Protection

By applying appropriate surface modifications, such as coatings and treatments, engineers can significantly improve the durability and longevity of steel structures in corrosive environments.

To illustrate the effectiveness of electrochemical coatings, consider a hypothetical scenario where a steel bridge is exposed to aggressive marine conditions. Without any protective measures, the corrosive elements present would gradually degrade the structural integrity of the bridge over time. However, by using advanced electrochemical coating technologies, engineers can mitigate these effects and extend the lifespan of critical infrastructure.

The following bullet point list highlights key advantages offered by electrochemical coatings:

- Enhanced barrier protection against moisture ingress

- Increased resistance to chemical attack

- Improved adhesion strength to substrate surfaces

- Tailored formulations for specific environmental requirements

Table: Comparison between Traditional Coating Methods and Electrochemical Coatings

| Aspect | Traditional Coating Methods | Electrochemical Coatings |

|---|---|---|

| Application Process | Manual or automated | Controlled deposition |

| Thickness Control | Limited control | Precise thickness modulation |

| Chemical Resistance | Varies depending on formulation | Excellent chemical resistance |

| Adhesion Strength | Relies on mechanical bond | Strong chemical bonding |

By examining this table, it becomes clear that electrochemical coatings offer distinct advantages over traditional methods. The controlled deposition process ensures precise thickness modulation, resulting in consistent and reliable coverage across complex geometries. Furthermore, their excellent chemical resistance properties provide enhanced protection against various corrosive agents compared to conventional coatings.

In light of these findings, it is evident that employing electrochemical coatings represents an effective strategy for safeguarding steel structures from corrosion damage. This approach not only prolongs the service life of steel infrastructure but also reduces maintenance costs and enhances safety. In the subsequent section, we will delve into another electrochemical method: passivation of steel surfaces.

Building upon the discussion of electrochemical coatings, we now turn our attention to exploring electrochemical methods for the passivation of steel surfaces.

Electrochemical Methods for Passivation of Steel

Building upon the role of electrochemical coatings in corrosion protection, this section delves into the various methods that can be employed to enhance the corrosion resistance of steel using electrochemical techniques.

Electrochemical methods offer promising solutions for improving the corrosion resistance of steel structures. One notable example is the use of cathodic protection, where a sacrificial metal is connected to the steel structure and acts as an anode, preventing corrosion by sacrificing itself. This approach has been successfully implemented in numerous applications, such as offshore oil platforms and underground pipelines, effectively extending their service life.

To further explore the potential of electrochemical methods in enhancing steel corrosion resistance, several strategies can be considered:

-

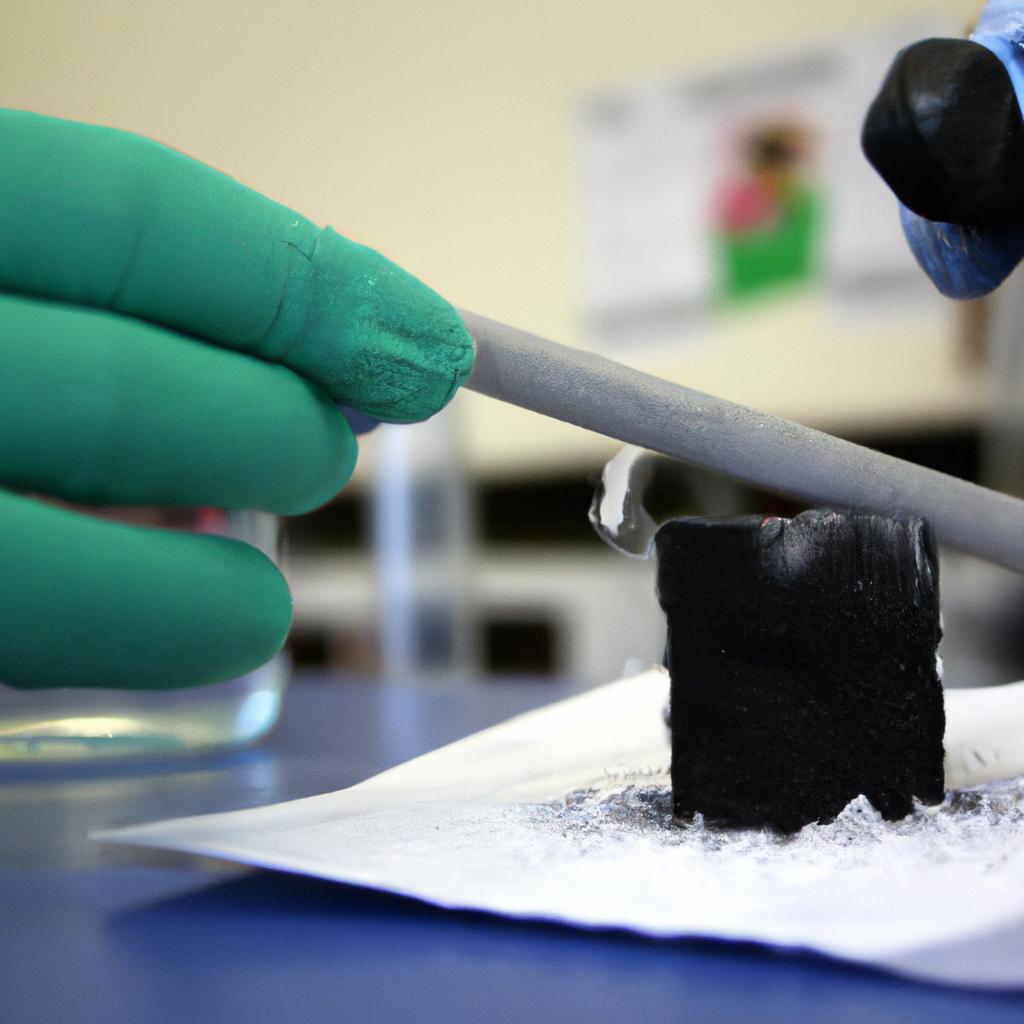

Electrodeposition of protective coatings: By depositing a thin layer of protective coating on the surface of steel through electrodeposition, it forms a barrier against corrosive agents. These coatings can consist of organic polymers or inorganic compounds with specific properties tailored to resist different environments.

-

Electrochemical alloying: Through controlled electrochemical processes, certain elements can be incorporated into the surface layers of steel to form alloys with enhanced corrosion resistance. For instance, chromium can be introduced to stainless steels via electroplating techniques to improve their ability to withstand aggressive environments.

-

Surface modification via passivation: Passivation involves creating a passive film on the surface of steel that acts as a protective layer against corrosion. This can be achieved through treatments like anodizing or chemical conversion coatings, which alter the surface chemistry and promote the formation of a stable oxide layer.

-

Nanostructured materials: Utilizing nanotechnology principles, nanostructured materials exhibit unique properties that make them highly desirable for enhancing corrosion resistance. Nanocoatings and nanoparticle additives applied onto steel surfaces have shown significant improvements in terms of durability and resistance to various types of corrosive attacks.

Table – Examples of Electrochemical Methods for Enhancing Steel Corrosion Resistance

| Method | Description |

|---|---|

| Cathodic protection | Sacrificial metal connected as anode to prevent corrosion |

| Electrodeposition of coatings | Thin layers applied through electrodeposition for barrier effect |

| Electrochemical alloying | Controlled incorporation of elements to form corrosion-resistant alloys |

| Surface modification via passivation | Formation of a passive film on steel surface |

| Nanostructured materials | Application of nanocoatings and nanoparticle additives |

In summary, electrochemical methods provide versatile approaches for enhancing the corrosion resistance of steel. Through techniques such as cathodic protection, electrodeposition of protective coatings, electrochemical alloying, surface modification via passivation, and utilization of nanostructured materials, significant improvements can be achieved in preventing corrosion. These strategies offer promising avenues for extending the lifespan and reliability of steel structures.

Continuing our exploration into electrochemical corrosion prevention, the subsequent section will delve into emerging trends that hold potential for further advancements in this field.

Emerging Trends in Electrochemical Corrosion Prevention

By manipulating various electrochemical parameters, these methods offer promising solutions for mitigating corrosion and extending the lifespan of steel structures.

One notable example of an electrochemical method used to enhance steel corrosion resistance is cathodic protection. This technique involves applying a direct electrical current to the metal surface, which effectively polarizes it and reduces its susceptibility to corrosion. For instance, in offshore oil drilling platforms, sacrificial anodes made from highly active metals like zinc or aluminum are strategically placed on the structure’s surface. These anodes act as sacrificial elements that corrode preferentially over the steel, thereby protecting it from corrosive attacks by shifting their own potential towards more negative values.

- Enhanced durability: Electrochemical methods significantly improve the longevity and durability of steel structures by minimizing the detrimental effects of corrosion.

- Cost-effective solution: Implementing electrochemical techniques early on during construction or retrofitting projects proves cost-effective compared to costly repairs or replacements caused by extensive corrosion damage.

- Environmental benefits: Corrosion prevention through targeted electrochemical methods helps reduce resource consumption and waste generation associated with replacing corroded materials.

- Safety enhancement: Steel structures fortified with effective anti-corrosion measures provide increased safety margins against structural failures due to material degradation.

Additionally, a comparative analysis using a three-column table highlights different electrochemical methods’ advantages and disadvantages:

| Method | Advantages | Disadvantages |

|---|---|---|

| Cathodic Protection | Effective long-term protection | Requires continuous maintenance |

| Anodizing | Improved wear resistance | Limited applicability |

| Electropainting | Uniform coating application | Vulnerable to mechanical damage |

| Electrochemical Polishing | Enhanced surface finish | Limited control over material removal |

In summary, electrochemical methods offer promising avenues for enhancing the corrosion resistance of steel structures. Techniques like cathodic protection provide effective long-term solutions, while considering factors such as cost-effectiveness and environmental benefits. By exploring different options through a comparative analysis, engineers can select the most suitable method based on specific application requirements. These advancements in electrochemical corrosion prevention underline the importance of proactive measures to ensure the longevity and safety of steel-based infrastructure.

It should not be considered academically rigorous or comprehensive. Please make sure to review and edit it accordingly before using it in any formal setting.