Founded in 1958, Framatome is a French multinational nuclear company that started using 3D technologies in 2015. It recently announced the development of its first 3D printed stainless steel fuel component. These top seat racks designed and manufactured at a nuclear power plant in Sweden operated by the Swedish company Vattenfall. They have been successfully installed in the plant as part of a multi-year irradiation program.

Last week, we presented the possibilities offered by additive manufacturing in the oil and gas industry, which is currently capable of producing parts with complex geometries to improve the performance of market solutions. It is a more cost-effective and efficient production method that allows components to be created in one go, without the need for time-consuming and costly assembly steps. Additive manufacturing also ensures the safety of processes and personnel working on site, a key point in the industry. The technologies have also gained ground in the nuclear industry, including for safety-critical parts in power plants. Indeed, last year Framatone also participated in the creation of a 3D-printed stainless steel fuel assembly channel attachment with Oak Ridge National Laboratory that was placed in the US commercial nuclear power plant. BWR.

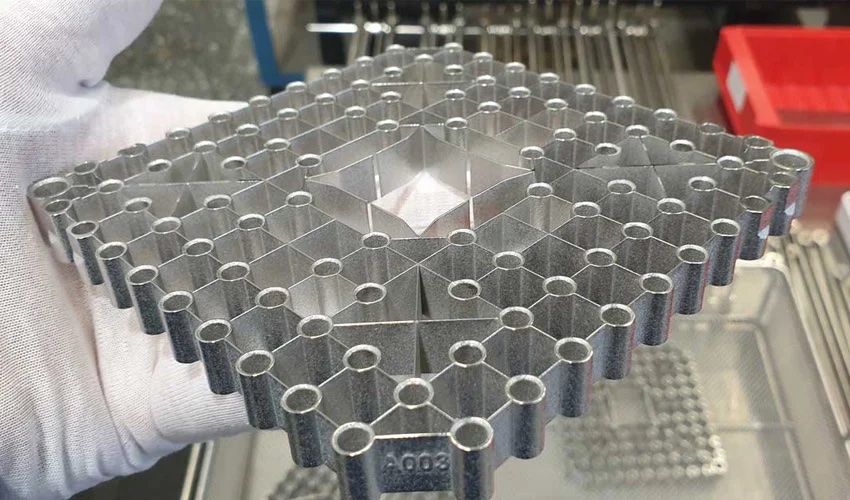

Different 3D printed parts from Framatome (photo credits: Framatome)

This latest announcement is another first for Framatome which has successfully installed the first 3D printed stainless steel part in a Swedish power plant. The upper grid of the tie plate is a non-structural support element that holds the fuel rods, the metal tubes in which are stacked cylindrical pellets of sintered uranium dioxide. The grid also serves to prevent large debris from entering the fuel assembly. Lionel Gaiffe, Deputy Managing Director, Fuel Business Unit, at Framatome, adds: “Advances in the integrity of components fabricated using 3D printing are revolutionary in generating safe and reliable low-carbon power for long-term operations. We appreciate Vattenfall for opening its doors and providing a springboard for future innovations and developments that will replace conventional manufacturing.

Traditionally, the manufacturing process for these grids involves several steps and requires a high level of operator supervision. In fact, they are often made from plates that are cut and stamped and then laser welded together. By leveraging additive manufacturing, teams can bypass these steps and come up with more complex designs to deliver more performance. Ella Ekeroth of Vattenfall Nuclear Fuel AB said:

“The safe operation of fuel assemblies is essential for Vattenfall. Along with this core principle, our contributions to the development of efficient and reliable manufacturing processes are in the best interests of the entire nuclear industry. The overall objective of these activities is to maintain and further improve safety and enable economically viable operations over the long term.

While waiting to learn more about the impact of this first 3D printed stainless steel component installed in a Swedish nuclear power plant, you can find the official press release HERE.

What do you think of this 3D printed stainless steel fuel component? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: Framatome